Recent Works at TakCFD

MEG Reclaimer – CFD Simulation

Description:

We performed a detailed CFD study on a MEG Reclaimer unit, utilizing VOF methodology, to evaluate liquid drain behavior using a vortex breaker under gravity drainage. The simulation captured transient liquid behavior, velocity profiles, and vortex formation dynamics to support performance optimization.

The items listed represent a portion of our engineering and simulation portfolio. Additional references and details can be provided upon request in accordance with confidentiality agreements.

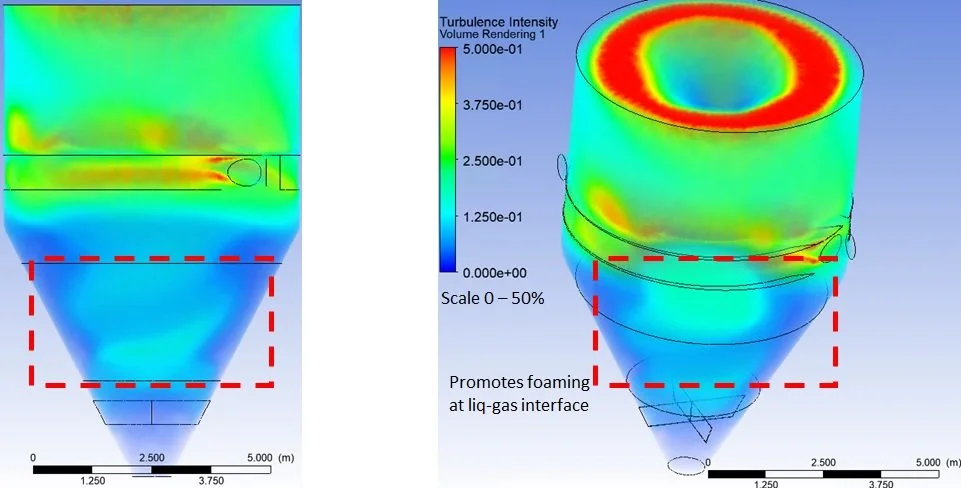

MEG Reclaimer – CFD Simulation

Description:

Following 1st MEG reclaimer simulation case, we introduced higher outlet pressure to assess its impact on flow stability and vortex suppression. The simulation revealed improved quasi-steady flow behavior and highlighted turbulence-induced foaming risks at the gas-liquid interface.

Trickle-Bed Reactor – CFD Verification

Description:

Using a hydrodynamic model from literature, we verified our CFD approach against a benchmark for trickle-bed reactors. The simulation demonstrated excellent agreement in liquid saturation patterns and confirmed the model’s reliability for industrial application.

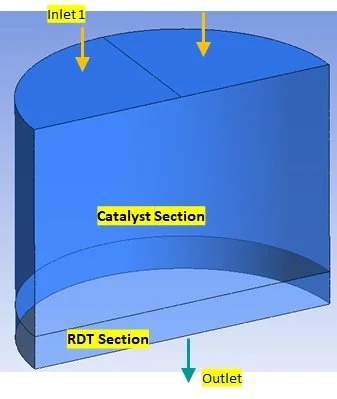

Trickle-Bed Reactor – CFD Simulation

Description:

We extended the verified CFD model to simulate a real-world trickle-bed reactor configuration for our client with layered catalyst and RDT sections. The study revealed how maldistribution persists across layers and quantified pressure drop across each bed.

Past experience of the team

Three-phase separator – CFD Study

Description:

We conducted an advanced CFD analysis of a three-phase separator for the client, using an Eulerian multiphase model to evaluate oil, water, and gas phase interactions. The study included a range of scenarios with varying droplet sizes and distributions to assess carry-over, interface stability, and phase separation efficiency. Special attention was given to turbulence effects, residence time, and interface behavior. Findings helped identify causes of water leakage into the oil compartment and led to targeted design recommendations—such as adjusting liquid level control strategies, refining inlet diverter design, and enhancing mist elimination systems.

Let’s Work Together

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and our specialist will contact you about beginning the proposal process.